Once you’ve confirmed that the clutch is becoming a limitation, the next decision is whether to stay with an OEM-style replacement or move to a performance clutch.

While both serve the same basic role, they’re engineered with very different priorities depending on torque, heat, and how the car is driven.

If you’re still diagnosing symptoms, this builds directly on our earlier guide covering when it’s time to upgrade your clutch, and focuses on what actually changes once an upgrade becomes necessary.

What OEM Clutches Are Designed For

OEM clutches are built around smooth engagement, light pedal effort, and long service life at factory power levels.

They’re optimized for predictable daily driving, quiet operation, and minimal learning curve in stop-and-go traffic.

For stock or lightly modified vehicles that aren’t exposed to repeated hard launches or elevated torque, an OEM-style clutch can still be the right solution.

In these cases, retaining factory-like behavior is often more important than increasing holding capacity.

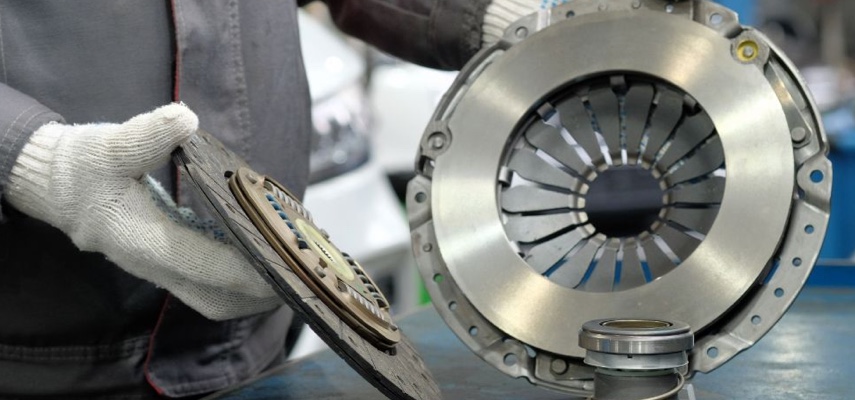

What Changes in a Performance Clutch

Performance clutches are designed to manage higher torque loads and increased heat.

To do that, several core elements differ from OEM designs, especially in applications where tuning, boost, or aggressive driving place more stress on the drivetrain.

Because of this, clutch selection is best viewed as part of the broader drivetrain system rather than an isolated component choice.

Friction Materials

OEM clutches typically use organic friction materials that emphasize smooth engagement.

Performance clutches may use upgraded organic compounds, ceramic blends, or multi-material discs to increase holding power under load.

These material differences are one of the main reasons performance clutches behave differently during engagement, especially as torque output increases.

Clamp Load and Pressure Plate Design

One of the most significant differences between OEM and performance clutches is clamp load.

Higher clamp force allows the clutch to hold more torque without slipping, but it often changes pedal effort and engagement feel.

This is also why stage ratings alone don’t tell the full story — pressure plate design and disc construction matter just as much.

Heat Management

Repeated spirited driving, higher boost levels, and frequent clutch engagement generate heat.

Performance clutches are engineered to tolerate higher temperatures without glazing or fading as quickly as OEM units.

Because heat affects more than just the clutch disc, clutch upgrades are often evaluated alongside flywheels during the same service interval.

How These Differences Affect Daily Driving

Increased holding power usually comes with trade-offs.

Depending on the clutch design, drivers may notice:

- Heavier pedal effort

- More immediate or abrupt engagement

- Occasional chatter at low speeds

That doesn’t mean performance clutches can’t work on the street.

It simply means the clutch needs to match the vehicle’s real-world use rather than aiming for maximum capacity by default.

Common Misconceptions About Performance Clutches

“Higher Stage Is Always Better”

Clutch stage ratings aren’t standardized across manufacturers.

A higher stage typically reflects increased holding capacity, but it also brings compromises that may not be necessary for every build.

“Any Power Increase Requires a Performance Clutch”

Mild bolt-ons don’t automatically exceed the limits of an OEM clutch.

If the clutch isn’t slipping and the car remains primarily street-driven, upgrading too early can reduce drivability without solving a real issue.

When a Performance Clutch Becomes the Right Move

- Clutch slip under load or during higher-gear pulls

- Increased torque from tuning or forced induction

- Frequent spirited driving or competition use

- Future power plans beyond OEM tolerances

At this point, clutch selection shifts from simple replacement to choosing a setup that supports consistent torque delivery and long-term reliability.

Where Brand Design Philosophy Matters

Not all performance clutches are built with the same goals.

Some prioritize street-friendly engagement with additional headroom, while others focus on maximum holding power for aggressive or track-oriented use.

Brands like Competition Clutch offer multiple clutch designs intended for different power levels and driving styles, making it easier to select a setup that fits the build rather than defaulting to the most aggressive option.

It’s also common for clutch decisions to align with broader build strategies that include engine and tuning platforms from manufacturers such as IAG Performance and COBB Tuning.

Real-World Clutch Kit Examples

To make the differences more concrete, here are a few clutch kits that illustrate common OEM-plus and performance-oriented approaches:

- ACT Heavy Duty Performance Street Sprung Clutch Kit, a common choice for increased torque with street-friendly engagement

- ACT Heavy Duty Performance Street Sprung Clutch Kit with Monoloc, often paired for consistency and improved response

- Spec 2013–2016 Ford Focus ST EcoBoost Stage 1 Clutch Kit, an example of platform-specific tuning for drivability and holding power

Final Thoughts

OEM and performance clutches are built with different priorities in mind.

The right choice depends less on labels and more on torque output, heat exposure, and how the car is driven day to day.

For builds that are ready to move beyond factory limitations, evaluating complete clutch kits is the most practical next step.

0 Comments for “OEM vs Performance Clutches: What Actually Changes?”